Note: This text was created with the help of AI.

- 1

- 2

- 3

- 4

- 5

- next page

Exclusive Offers on 3D Printers

A 3D printer is a special machine with which you can produce three-dimensional models. You can use a variety of materials, whether solid or liquid, metal, plastic or sand. Most 3D printers are used in industry to create specific parts or prototypes. But 3D printers are constantly evolving and becoming more popular in the home as well. So they offer you many exciting possibilities to create your own three-dimensional workpieces at home.

A 3D printer can work with a wide variety of materials, such as liquid plastic, powdered metal or even ceramics and sand. There are various printing processes for creating three-dimensional workpieces. In most cases, the material is heated to a very high temperature and liquefied. In the meantime, it is sprayed layer by layer onto a work plate, similar to a conventional printer. With the help of laser beams, the material is hardened and your 3D model is ready. This layer-by-layer process is called additive manufacturing.

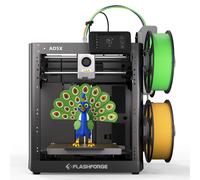

There are several different printing methods for a 3D printer. The best known is the FDM method (Fused Deposition Modeling), which is best suited for home use. This process is similar to a hot glue gun: material is heated, liquefied, deformed, and then hardened. The method is relatively cheap and fast, but it is not always very precise. The parts produced are very resilient, but have a noticeable corrugation.

Another method is the SLS/SLM method (Selective Laser Sintering/Melting). Here only powder is used as material and no filament. The three-dimensional object is created by spreading the powder evenly and thinly and then hardening it with a laser beam. This method is relatively expensive and has so far only been used in industry. There is also the SLA method (stereolithography). For this, a basin of synthetic resin and a UV laser are used, which produce particularly fine, precise 3D objects from synthetic resin. So far, stereolithography is also only possible in industry.

A 3D printer usually takes a relatively long time to create prints. Of course, this depends on what you are printing and the size and complexity of the object. The more nooks and crannies it has, the more complex it is and the longer it will take to create. For example, a small whistle can be created in an hour. An espresso cup will take several hours, while a coffee cup will take at least half a day.

There are many different materials for your 3D printer. Some are inexpensive and especially suitable for beginners, others are very demanding to process. You can find the different materials in numerous online shops and order them conveniently to your home. Your local hardware store is also sure to have a variety of materials for your 3D printer.

It is difficult to generalise. Depending on the size and complexity of the objects and models you want to build, 3D printers need more or less space. Remember that a 3D printer is not comparable in size to a conventional printer, for example an inkjet or laser printer. You therefore need a lot more space and also need to look for a suitable location because of the noise emitted by the 3D printer.

You need different software to create models. There is usually a distinction between 3D design and modeling software and 3D scanning software. Some are free and ideal for beginners, while others are more sophisticated and costly.

The most popular 3D modeling and 3D design software are Autodesc 123D, Thinker CAD, Fusion 360, Blender, Grab CAD, Free CAD, Sketch up, Open SCAD and Simplify 3D. Some of the most popular slicer and 3D printer software include Cura, Repetier Host, Slic3r and Replicator G.

Exclusive Offers on 3D Printers

If you’re on the lookout for an innovative way to bring your ideas to life, 3D printers are making waves in the manufacturing and creative worlds alike. With a range of options available on pricehunter.co.uk, you can explore various models that fit your needs and budget. Whether you’re a hobbyist, educator, or professional, there’s something for everyone in this dynamic market.Types of 3D Printers

When considering a 3D printer for your needs, it’s crucial to understand the different types available. Each type serves distinct purposes and has unique capabilities.- FDM Printers: The most common type, great for beginners and affordable.

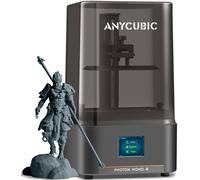

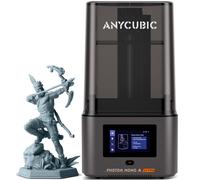

- SLA Printers: Perfect for high-resolution prints, often used in jewelry and dental industries.

- SLS Printers: Ideal for industrial-grade production, using powdered materials for durability.

- Multi-material Printers: Capable of printing with different materials simultaneously for complex projects.

- Delta Printers: Known for speed and precision, suitable for intricate designs.

Popular Brands to Consider

Choosing a reputable brand can make a world of difference in your 3D printing experience. Renowned brands are known for their reliability and customer support.- Creality: Popular for their accessible and user-friendly models, excellent for beginners.

- Prusa: Offers high-quality, customizable printers that are a favorite among enthusiasts.

- Anycubic: Known for affordability while still delivering impressive quality.

- Ultimaker: Targets professionals with high-performance and versatile printers.

- Formlabs: Specializes in SLA printers, perfect for those needing exceptional detail.

Key Features to Look For

Different features can greatly enhance your 3D printing experience. Understanding these can help you choose the right model.- Build Volume: Determine the maximum size of your prints; larger volumes allow for more flexibility.

- Layer Resolution: Affects print quality; finer layers yield more detailed outputs.

- Print Speed: Faster printers can save you time, but might compromise quality.

- Connectivity Options: USB, Wi-Fi, and Ethernet capabilities can enhance usability.

- Software Compatibility: Ensure the printer works with popular slicing software for ease of use.

Usage Scenarios for 3D Printers

Understanding how you plan to use a 3D printer will help narrow down your options. Different scenarios require different features.- Hobbyists: Ideal for personal projects, custom models, or prototypes.

- Education: Great for schools to spark creativity and teach design and engineering principles.

- Prototyping: Essential for businesses to test and create new products rapidly.

- Art and Design: Artists use 3D printers for unique sculptures and installations.

- Medical Applications: Custom prosthetics and models for surgical planning are made easier with 3D printing.

Essential Accessories for Your 3D Printer

Accessories can enhance your printing experience and ensure quality results. Knowing what to include can save you time and frustration.- Filament: Choosing the right material is essential; options include PLA, ABS, and PETG.

- Print Bed Adhesive: Helps prints stick better to the bed, reducing warping.

- Cleaning Tools: Keep your printer in top shape with brushes and scrapers.

- Calibrating Tools: Essential for maintaining precision and print quality over time.

- Upgraded Parts: Consider enhancements for better performance, such as hotends or cooling fans.

Note: This text was created with the help of AI.